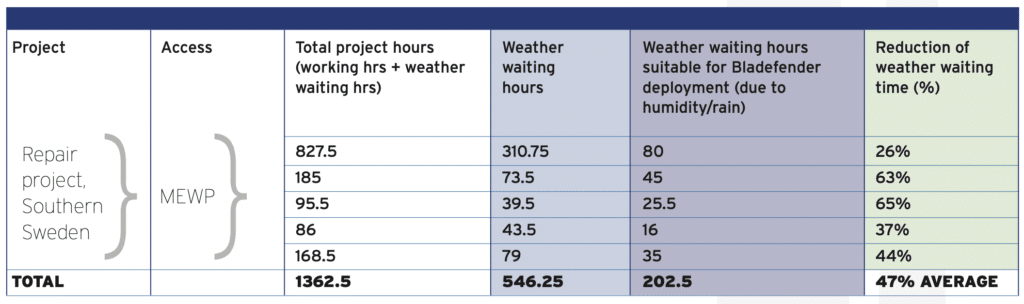

Well, with our state of the art Bladefender, we could help make this possible (see table below)! That means highly efficient projects with reduced turbine downtime, all the while working with the safest possible practices.

We’ve listened closely to our customers’ feedback over the last decade and one resounding issue that we’ve been hearing time and time again is the obstacle of relentless weather waiting. With this in the forefront of our minds, we have spent the last two years working tirelessly to develop a solution to our customers’ number one problem, we introduce to you the Bladefender.

Developed during 2018 and introduced in the 2019 season, the Bladefender system is a covered, environmentally-controlled habitat that attaches to the basket of the skylift (MEWP). Whilst allowing full access around the blade, it also provides the technician with an environment that better suits the materials required. One of the challenges faced up until now has been that composite materials used for repairing blades do not perform as necessary in extreme temperatures. Typically, an epoxy repair resin requires 15°c – 25°c and a maximum relative humidity of less than 70% to set effectively, but with the addition of the Bladefender we can accurately control the environmental conditions around the repair area to ensure that we’re carrying out the highest quality repair, inline with DNV GL standards, every single time.

This safe, protected and comfortable environment enables the team to continue to work in more adverse conditions such as light

rain and high humidity, as well as particularly high and low temperatures. In many cases this can open up the window for blade repair and maintenance, allowing the technicians to work year-round and reducing sub-optimal operation and turbine downtime.

Ultimately, with the use of the Bladefender, technicians can spend more time up tower carrying out maintenance jobs and less time on the ground waiting for good weather conditions – It even allows us the possibility of working after daylight hours.

Wind farm asset owners can benefit from reduced weather waiting hours since technicians are able to complete maintenance activities at a quicker rate, meaning that turbines can be brought back online and begin generating revenue again much sooner.

Could the Bladefender benefit you? Get in touch so we can start optimising your blade works today!

Quick glance Bladefender Fact File

- The modular design of Bladefender allows for fast and simple on-site installation taking no longer than 15 minutes.

- The internal environment can be adjusted to support application of rapid-curing UV-based blade coatings, such as RENUVO.

- Using Bladefender reduces weather waiting factors, due to high humidity and rain, by 47%.

- Designed by Bladefence and approved by the access platform manufacturer, Bronto Finland, the system has a maximum load of 350kg and a 12.5m/s wind-speed limit.

- Bladefender allows the technician to easily control the work-area temperature and humidity, with a dehumidifier and heater included as part of the system.

- Bladefender allows maintenance work to be carried out more quickly and efficiently than rope- or MEWP-enabled access.

- The system is provided with safety documentation, risk assessment and evacuation plan.

- Bladefender does not require additional logistics, it can travel with our truck mounted access platforms and our team can set it up without external help.

Click here to read more about Bladefender in a recent Windpower Monthly article!